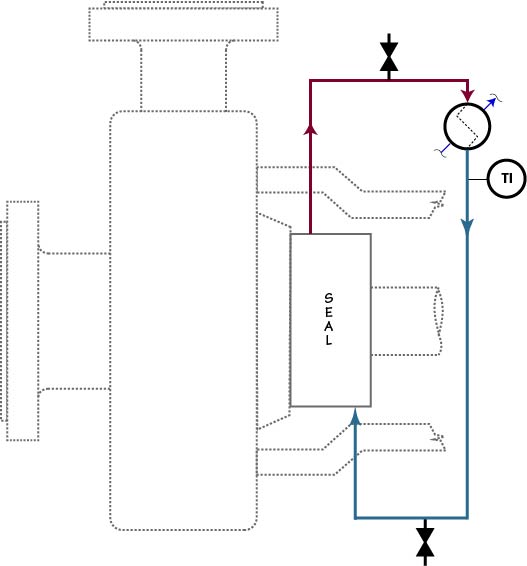

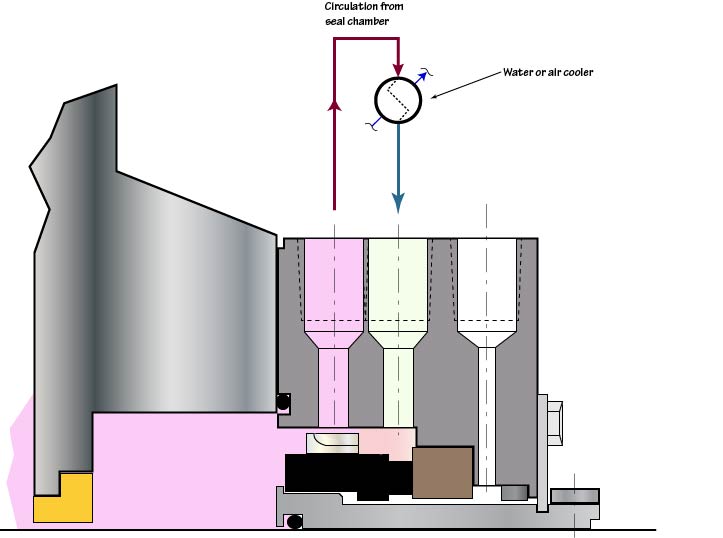

Plan 23 is a closed loop circulation system used on hot applications for flushing and cooling single seals. In Plan 23, a pumping ring in the seal chamber circulates product through a heat exchanger and back to the seal chamber. A close clearance throat bushing isolates the cool seal chamber from the hot pump.

The heat exchanger may be either water cooled or air cooled. It should be sized to remove heat soak from the hot pump body as well as heat generated at the seal faces.

Plan 23 probably was first used in hot water services such as boiler feed water. It is very efficient and is preferred instead of Plan 21. However, proper venting is essential to the successful operation of Plan 23.

Plan 23 systems are not controlled directly. The circulation rate depends on the performance of the pumping ring within the closed loop system. The pumping ring, heat exchanger and piping are selected to produce the desired conditions. Heat soak as well as heat generation must be considered in determining the desired circulation rate.