In spite of all its excellent specifications, recommendations, tutorials, etc., etc., API 682 is not a general purpose standard for mechanical seals. Here is a partial list of seals that API 682 does not address:

- large seals

- high pressures

- mixer seals

- rotary pump seals

- wedge/chevron/ucup

- outside mounted

- common mating ring

- shaft mounted

- hook sleeve mounted

- automotive water pump seals

- stern tube seals

- split seals

- elastomeric bellows seals.

It appears that the 5th Edition of API 682 will include somewhat larger seals and higher pressures. Mixers and rotary pumps could, of course, use API 682 seals provided those seals would fit into the seal chamber. Wedges, chevrons or U-cups for dynamic secondary sealing elements were intentionally omitted in favor of O-rings. Outside mounted seals were intentionally omitted in favor of inside mounted seals. Shaft mounted seals and hook sleeve mounted seals were omitted in favor of cartridge mounted seals. Dual seals using a common mating ring were omitted in favor of requiring a mating ring for each seal ring. Automotive water pump seals as well as similar small utility seals and stern tube seals are far outside the scope of API 682. Split seals have very different design for special applications and were never considered for inclusion in API 682.

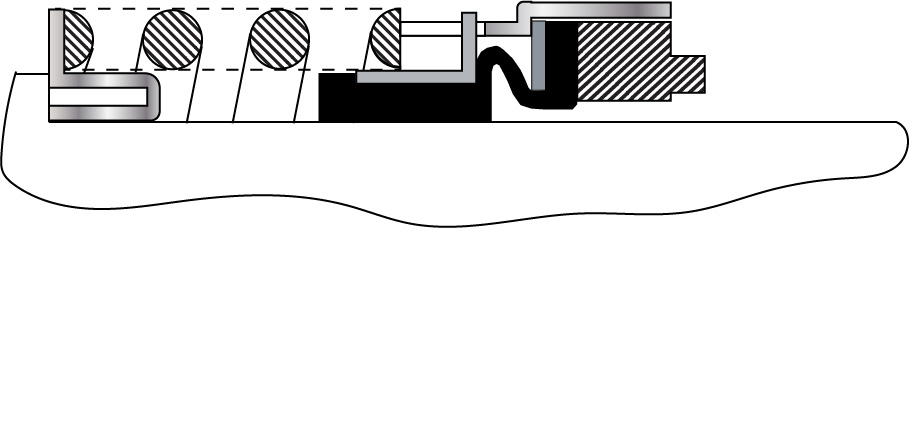

Interestingly, API 682 does not address one of the earliest, most popular and proven mechanical seals: the elastomeric bellows seal. The omission of elastomeric bellows seals was intentional because some members of the 1st Edition Taskforce felt that elastomeric bellows seals were difficult to install. This can be true; however, since API 682 considers only cartridge seals, installation of elastomeric bellows seals is simplified and furthermore would be done by the seal OEM.

In the mid 1930’s Crane Packing Company licensed a mechanical seal design from Chicago Rotary Seal. By the late 1930s, mechanical seals began to replace packing on automobile water pumps. At first only the more expensive automobiles used mechanical seals in the water pump. The famous Jeep of WWII used a Crane elastomeric bellows seal in the water pump. After WWII, all automobile water pumps used mechanical seals. Through several Crane patents, their design evolved into the full convolution elastomeric bellows seal of today.

In 1943, under the direction of Carl E. Schmitz and designed by Russ Snyder, Crane Packing Company began work on what became its Type 1 and Type 2 rubber bellows mechanical seals. Don Piehn, a draftsman still in high school, did the detailed drawings. The Type 1 and Type 2 seal names were adopted about 1946. Prior to 1946, Crane seals did not have number/type names. The Crane seals that had been used in WWII jeeps and later other automobile water pumps came to be called the Type 3 and Type 4 but actually preceded the Type 1 and Type 2.

Today, there are many manufacturers of elastomeric bellows seals. Elastomeric bellows are very popular and also very reliable but they are not considered by API 682.