Apparently, the rules and guidelines for conducting a hydrostatic test on pressure vessels – including pumps – are about to be changed. Perhaps those rules have already been changed and I’ve simply missed hearing about them. I blame that on retirement.

The hydrostatic test is the way in which pressure vessels are tested for leaks. The test involves filling the vessel with a liquid, usually water, and pressurizing it to the specified test pressure. In my career, the rule for determining the hydrostatic test pressure has been to simply multiply the Maximum Allowable Working Pressure (MAWP) by 1.5. That is, suppose a certain vessel has an MAWP of 600 psig; it would be hydrostatically tested at 900 psig. Of course, there are other details such as the duration of the test, variations based on operating temperature, etc. But basically, the hydrostatic test pressure has been 1.5 x MAWP for many years – certainly since the 1950s. However, it has not always been that way.

Here’s an interesting little anecdote that I was told many years ago. I may not have it quite right and, for all I know, it may not even be true, but here goes. In the 1970s, I was told that very long ago, the practice was to test pumps at 2 x MAWP. Perhaps this was because pumps are manufactured from castings. Anyway, there was a pump standards meeting (perhaps this was even an early form of an API standards meeting) and a requirement was written to hydrostatically test pumps at 1.5 x MAWP. After the meeting, the chief engineer for a major pump manufacturer was buying drinks for everyone at the bar. Surprised by his generosity, a fellow committee member remarked that the 2x hydrostatic test must have been difficult. “Not at all”, said the chief engineer, “In fact, I just increased all my pressure ratings by 33%!” That is, pumps previously rated for 600 psig MAWP but hydrostatically tested at 1200 psig could still be hydrostatically tested at 1200 psig but then rated for 800 psig MAWP!

I’ve been told that the multiplication factor for determining the hydrostatic test pressure will be changed from 1.5 to 1.3 according to the ASME Pressure Vessel Code Section VIII. Apparently this will be applied to both pumps and piping. The same multiplier will probably be used for API 682 reservoirs such as are used with Piping Plan 52 and 53. The pertinent 4th Edition clauses for reservoirs now read:

8.3.6.2.8 The reservoir is part of the pump piping system. Unless otherwise specified or required by local code, the reservoir shall be designed, fabricated, and inspected in accordance with ISO 15649 or ASME B31.3 using piping components.

8.3.6.2.9 If the reservoir is built entirely of piping components, ISO 15649 or ASME B31.3 can be applied and provides adequate design for the reservoir just as it does for the pump suction and discharge piping. It is the user’s responsibility to ensure that local codes do not require that reservoirs be built in accordance with a pressure vessel code such as EN 13445 or ASME VIII, Division 1.

With this wording, the default is a pipe based reservoir but an ASME certified reservoir is an option. I hope we will be able to continue this approach in 5th Edition but I’m uncertain about higher pressure reservoirs. From my past experience, old notes and browsing, here’s what I’ve learned.

ASME Certified Pressure Vessels

ASME certified pressure vessel fabricators undergo a rigorous program to ensure compliance with the rules and regulations of the ASME Boiler and Pressure Vessel code. For unfired pressure vessels, these requirements are given in ASME VIII, Division 1 (EN 13445). There are two variations of certification: “U” stamp and “UM” stamp.

“U”stamped pressure vessels are required to have a 3rd party ASME inspector review and approve the calculations as well as inspect certain stages during manufacture of the reservoir. This inspector also witnesses the ASME hydrostatic test which, apparently, is now 1.3 x MAWP. This means that U stamped vessels cannot be manufactured in advance; that is, the U stamped vessel is customized for a particular service, has a serial number and therefore cannot be a stocked item. The fabricator undergoes an ASME inspection every three years.

In contrast to the U stamped vessels, there is a “UM” stamped vessel which is also subject to the same ASME specifications. However, the “UM” stamped vessel is limited to a maximum of 1.5 cubic feet for a 600 psig rating and 600 psig is the maximum permitted pressure for the UM stamp. ASME 3rd party inspection is not required; therefore “UM” vessels can be manufactured in advance, they do not have a serial number and they can be stocked as an inventory item. The UM fabricator is inspected annually by ASME.

Pipe Based Reservoirs

Pipe based reservoirs for API 682 sealing systems must be built entirely of piping components and ASME B31.3, “Process Piping”, (ISO 15649) is the governing standard. As far as I can tell, ASME B31.3 now requires hydrostatic testing at 1.3 x MAWP.

Mechanical Seals

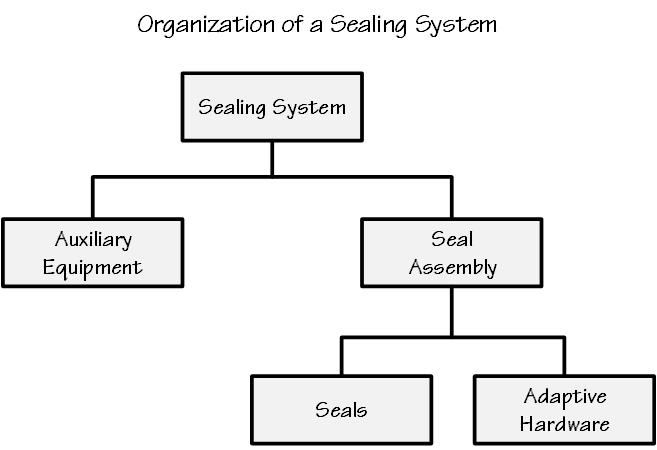

It should be noted that the mechanical seal is not considered to be part of the pump pressure vessel and therefore does not fall under the pressure vessel rules. Seal manufacturers have several pressure ratings for their products. API 682 recognizes a static pressure rating, a dynamic pressure rating and a hydrostatic pressure test rating (see the SealFAQs version of these definitions). Each seal OEM seems to use a different and proprietary method for determining these pressure limits.